| Area | Brief of observation | Observation |

| Applicable to All Department | Building access records showed an employee responsible for collecting samples did not enter the buildings where the samples were documented to have been collected or that the employee was in a different building at the time the sample was documented to have been collected. |

On June 2, 2022, (b)(4) samples were documented to have been collected in the production block building for points (b)(4). Building access records show the employee documented to have collected the samples used their badge to access the Documentation Cell at (b)(4) in the quality block, a different building. Additionally, the badge access records show no entrance or exit from the changing room or (b)(4) required for entrance and exit of the production block manufacturing area where (b)(4) are located. The badge access records also show the employee entered the service floor of the production block building at (b)(4) and exited the service floor at (b)(4). During this time period, the sampling records document point (b)(4) was sampled at (b)(4)and (b)(4)point was sampled at (b)(4) . (b)(4) are located in the quality block, a different building. |

| Applicable to All Department | Building access records showed an employee responsible for collecting samples did not enter the buildings where the samples were documented to have been collected or that the employee was in a different building at the time the sample was documented to have been collected. |

On January 7, 2021, (b)(4) sample for (b)(4) was documented to have been collected at 11:03 on the service floor in the production block. Badge access records show the employee documented to have collected the sample leaving the microbiology laboratory at 11:03 in the quality block, a different building. Additionally, the badge access records show no entrance or exit from the service floor where (b)(4) is located.

The sampling records also show the employee collecting a (b)(4) sample from (b)(4) (12:32) and (b)(4) (12:37) inside of the production block. Badge access records show the employee leaving the microbiology laboratory at 12:34 and entering the quality dining area at 12:36, both of which are in the quality block, a different building. Additionally, the badge access records show no entrance or exit from the changing room or (b)(4) required for entrance and exit of the production block manufacturing area where (b)(4) and (b)(4) are located. |

| Applicable to All Department | Building access records showed an employee responsible for collecting samples did not enter the buildings where the samples were documented to have been collected or that the employee was in a different building at the time the sample was documented to have been collected. |

On January 29, 2021, (b)(4) sample for (b)(4) was documented to have been collected at 12:37 inside the manufacturing area in the production block. Badge access records show the employee documented to have collected the sample entering the quality dining room at 12:35 in the quality block, a different building.

The sampling records show the employee collecting a (b)(4) sample from (b)(4) at 13:02 on the service floor of the production block. Badge access records show the employee leaving a changing room in the quality block, a different building, at 13:03. |

| Applicable to All Department | Building access records showed an employee responsible for collecting samples did not enter the buildings where the samples were documented to have been collected or that the employee was in a different building at the time the sample was documented to have been collected. |

On August 9, 2021, (b)(4) sample for (b)(4) was documented to have been collected at 12:37 inside the production block. Badge access records show the employee documented to have collected the sample entering the quality dining room at 12:39 in the quality block, a different building. Additionally, the badge access records show no entrance or exit from the changing room or (b)(4) required for entrance and exit of the production block manufacturing area where the employee had collected (b)(4) samples. |

| Applicable to All Department | Building access records showed an employee responsible for collecting samples did not enter the buildings where the samples were documented to have been collected or that the employee was in a different building at the time the sample was documented to have been collected. |

On October 22, 2021, (b)(4) samples were collected from points (b)(4) and (b)(4) from the service floor in the production block. Badge access records show no entrance or exit from the service floor where these points are located for the employee documented to have collected the samples. |

| Applicable to All Department | Building access records showed an employee responsible for collecting samples did not enter the buildings where the samples were documented to have been collected or that the employee was in a different building at the time the sample was documented to have been collected. |

On November 17, 2021, (b)(4) samples were collected from points (b)(4) inside the manufacturing area in the production block. Badge access records show no entrance or exit from the changing room or (b)(4) required for entrance and exit of the production block manufacturing for the employee documented to have collected the samples. |

| Applicable to All Department | Entries were not made into GMP records contemporaneously. | On August 3, 2022, the logbook for incubator MQAWIC06 did not have an end of incubation date, time, and signature for (b)(4) samples collected on July 27, 2022, which had been removed from the incubator and read on August 1, 2022, or (b)(4) samples collected on July 28, 2022, which had been removed from the incubator and read on August 2, 2022. |

| Applicable to All Department | Entries were not made into GMP records contemporaneously. | On August 3, 2022, the (b)(4) logbook 001 had an incomplete entry missing the source of the isolate, date, and analyst signature for the use of the instrument for isolate IHI033-22 analyzed on July 29, 2022. |

| QA | Written procedures are not drafted, reviewed and approved by the appropriate organizational units and reviewed and approved by the quality control unit. | Review of APQRs of (b)(4) revealed that based on the calculated process capability (Cpk) for dissolution attributes, the manufacturing process is not capable of consistently manufacturing products that meet the dissolution specifications. |

| QA | Written procedures are not drafted, reviewed and approved by the appropriate organizational units and reviewed and approved by the quality control unit. | CAPA 1207288 proposed to address the dissolution OOS trend for (b) (4) with changes to the amount of (b) (4) utilized during the(b) (4) process and increase (b) (4) time. Review of records associated with the CAPA revealed that there is no adequate plan designed to evaluate the effectiveness of these changes. In addition, review of in-process data for (b) (4) of (b) (4) revealed that the process is skewing towards the higher (b) (4) limit, and this information was not considered during the recommendation for corrective actions. |

| QA | Written procedures are not drafted, reviewed and approved by the appropriate organizational units and reviewed and approved by the quality control unit. | Review of APQRs for the year 2020-2021 of (b) (4) as well as SOP 000807 revealed that data from in-process controls quality attributes are not evaluated during the yearly evaluation of process performance capability. |

| Manufacturing | Written procedures are not drafted, reviewed and approved by the appropriate organizational units and reviewed and approved by the quality control unit. | During compression at tablet press MPDRCM03 of (b) (4) mg tablets, batch # (b) (4) executed on August 3, 2022, we observed that the reject level for the process was set up using average compression force from 2018 instead of using the values obtained during set up for the batch currently being manufactured. The rejection limit is susceptible to change based on the compression force that is observed during equipment setup for each batch that is manufactured. |

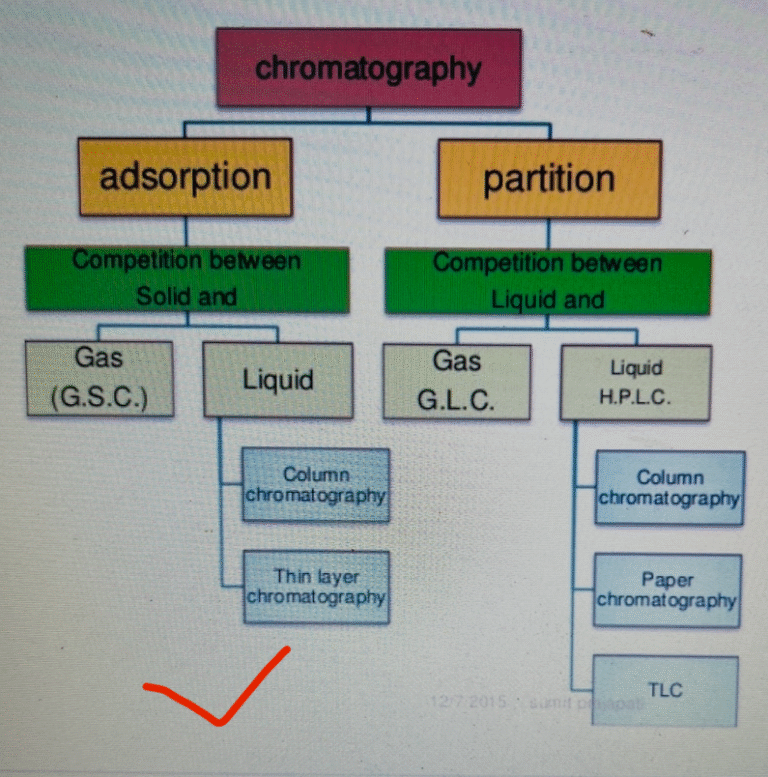

| QC | Laboratory records are deficient in that they do not include a complete record of all data obtained during testing. | When an analyst processing chromatography data determines the existing processing method is not appropriate or chooses to use a different processing method for samples within the same sample set during impurities analysis, the original chromatogram is not saved. The analyst can integrate the chromatogram and see the results within the software, but does not save the result. To change the processing method the analyst must document that the integration was inappropriate and get approval on Form000505. But the original chromatogram is not saved to justify the changes to the processing method were necessary. |

| QC | Laboratory controls do not include the establishment of scientifically sound and appropriate test procedures designed to assure that drug products conform to appropriate standards of identity, strength, quality and purity. |

Procedures to ensure accurate and consistent integration of chromatographic peaks have not been established. The analysts can choose the integration algorithm and manually enter timed integration events into the processing methods. Procedures have not been established to ensure the appropriate and consistent use of these timed integration events. |

| QC Micro | Laboratory controls do not include the establishment of scientifically sound and appropriate test procedures designed to assure that drug products conform to appropriate standards of identity, strength, quality and purity. |

In-housed prepared (b)(4) microbiology media plates used for testing (b)(4) samples collected July 29, 2022, showed indications of desiccation on August 4, 2022, prior to the end of incubation. This included cracking of the media and media pulling away from the edges of the plate on eight of the (b)(4) plates. |

| QC Micro | Laboratory controls do not include the establishment of scientifically sound and appropriate test procedures designed to assure that drug products conform to appropriate standards of identity, strength, quality and purity. |

Procedures have not been established to ensure the potential source of microorganisms identified from the environmental monitoring program are evaluated. For example, Enterococcus faecium, an organism that may be associated with fecal contamination, was identified in Compression Room (b)(4) in 2021 and Dispensing Room (b)(4) in 2020. It is included in the isolate library and colonies with similar morphology do not require any additional identification. |

| QC | Written procedures are not followed for the testing of components. | Procedure SOP000858 “Reduced Testing Procedure” requires confirmed OOS results to be considered in determining whether reduced testing should be approved. Report MP-R/AS/1008 was used to justify reduced testing for the API (b)(4) The report stated it would not consider a previous batch that was rejected for a particle size distribution OOS.

After approval of reduced testing, subsequent investigations, including 911981, 1004103, 1008080, and 1026612 into dissolution failures that resulted in rejected batches of finished (b)(4). Tablets identified the particle size of the API was critical and attributed more fines in API lots as a root cause. The approved reduced testing for particle size distribution in (b)(4) API was not reevaluated as described in procedure SOP000858. |